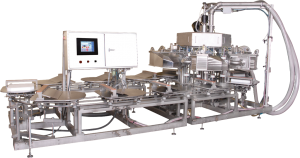

RC-300 Rotary Chamber

Features

Features

Reduced Operation Cost:

- Stop being handcuffed to only one supplier

- Patented Sealing System

- Water cooled hold down and continuous temperature sealing element. Minimized “pulled in” corners and reduced replacement of sealing elements (6-8 months replacement time based on average production schedule).

- Seals through any bag thickness, and through creases or contaminates.

Reduced Maintenance Cost:

- 300 Series Stainless Steel construction

- Most parts available “off the shelf” for economical and quick repair

- Designed for food packaging heavy wash-down environment

Reduced Downtime:

- Easier to maintain and repair – the wear parts are designed to be accessible without complete disassembly.

- State-of-the-art electronics

Faster Production:

Averages 25 packages per minute

Easy Operation:

PLC controlled using a 10” touch-screen display